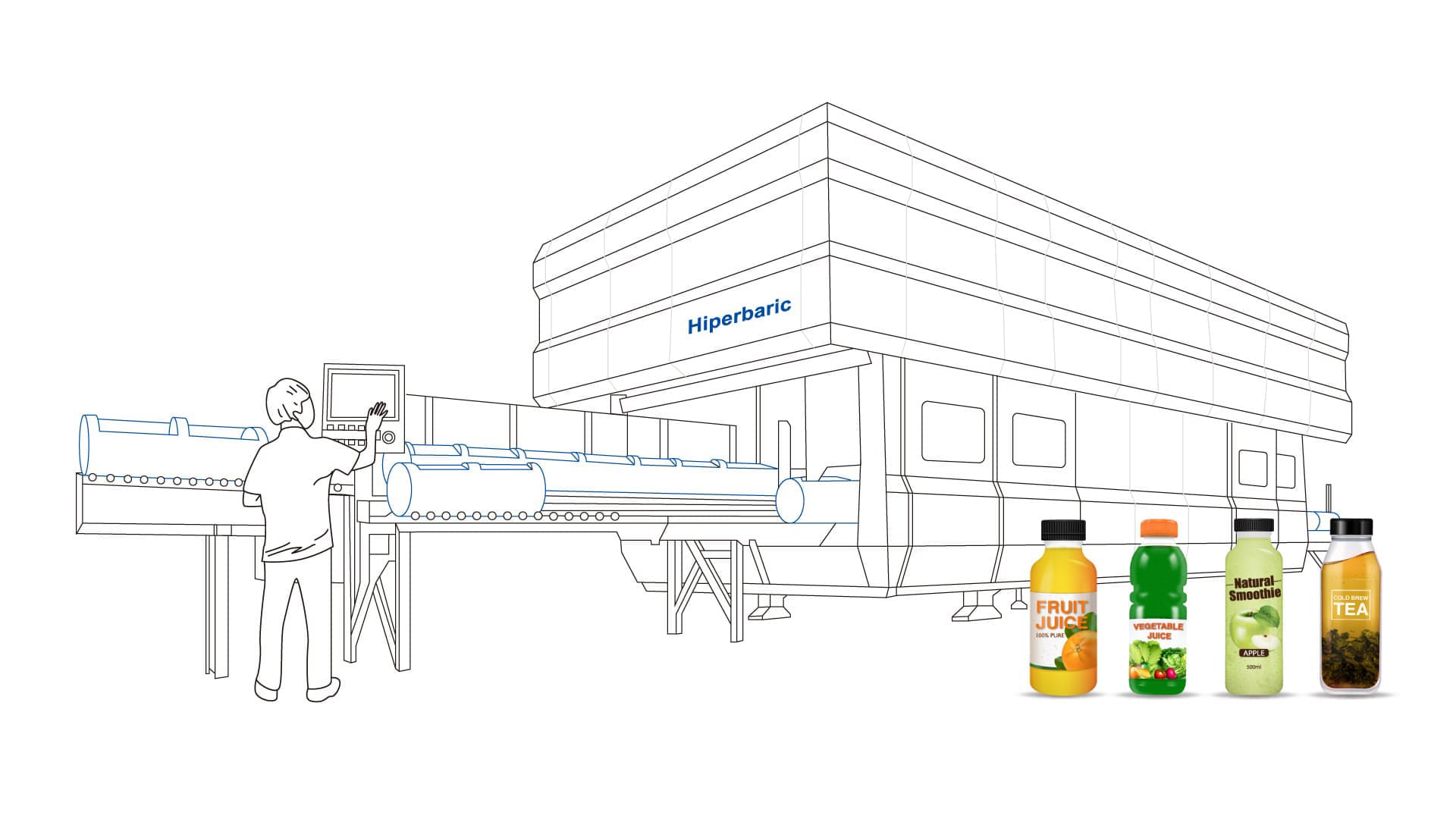

What is HPP (High Pressure Processing)?

A high-pressure, non-thermal technology for fresh and safe food

HPP uses liquid water to apply 100–600 MPa (1,000–6,000 atmospheres) of pressure uniformly to sealed foods at ambient temperature. The extreme pressure inactivates microorganisms, extends shelf life, and preserves natural taste and nutrients, all without the use of heat.

HPP Triple Advantage

We impose stringent quality control procedure from the point of raw materials arrived factory until squeezed juice packed in the bottle and while using HPP(High Pressure Processing) in the production process.

HPP maintains its flavor, color and composition intact, which is precisely what today's consumer demands.In the case of fruit and vegetable juices, this technology preserves all its nutrients, vitamins, antioxidants and its flavor with a taste that is better than homemade freshly squeezed fruit juice, but with an extended shelf life and food safety guarantee.

Production Flow

Incoming Inspection

STEP 1

Raw material Selection /

Quality Check

Materials Processing

STEP 2

Sorting / Washing

STEP 3

Juice Squeeze

STEP 4

Blending

STEP 5

Bottle Washing

Product Packaging

STEP 6

Filling & Capping

STEP 7

HPP

[High Pressure Processing]

STEP 8

Packing / Palletizing

Storage and Delivery

STEP 9

Storing (-18°C)

STEP 10

Delivery (-18°C)

Fast / Safe / Pure

Advanced Cold Storage Facilities

To ensure optimal post-production storage for HPP products, we provide comprehensive cold chain services featuring +12°C docks, +5°C buffer zones, and -20°C freezers.

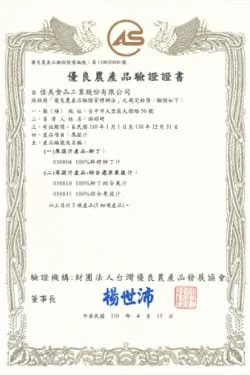

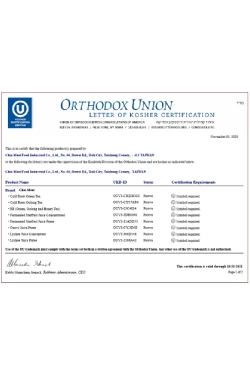

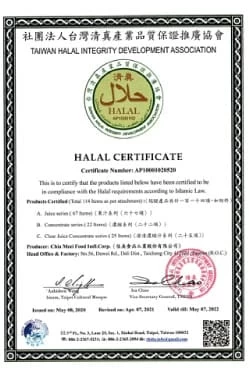

Certificates

Our HPP Line can produce juice, smoothie, tea and have awarded of various types Certification such as HACCP, CAS, Kosher and HALAL standards.

CAS

Koser

HALAL