ADVANCED PRODUCTION FACILITIES

As the Packaging is adding the value for the product, our premier quality and packaging will be your weapon when facing the competitive market. We apply the most advanced equipment to produce the upmost quality to satisfy our customers. Hon Chuan acquired various international quality and management certifications, such as ISO-9001、ISO-22000、HACCP、OHSAS18001、TOSHMS、FGMP and so on. Those certifications not only proof our quality and safety but also evidence that our product is your best choice.

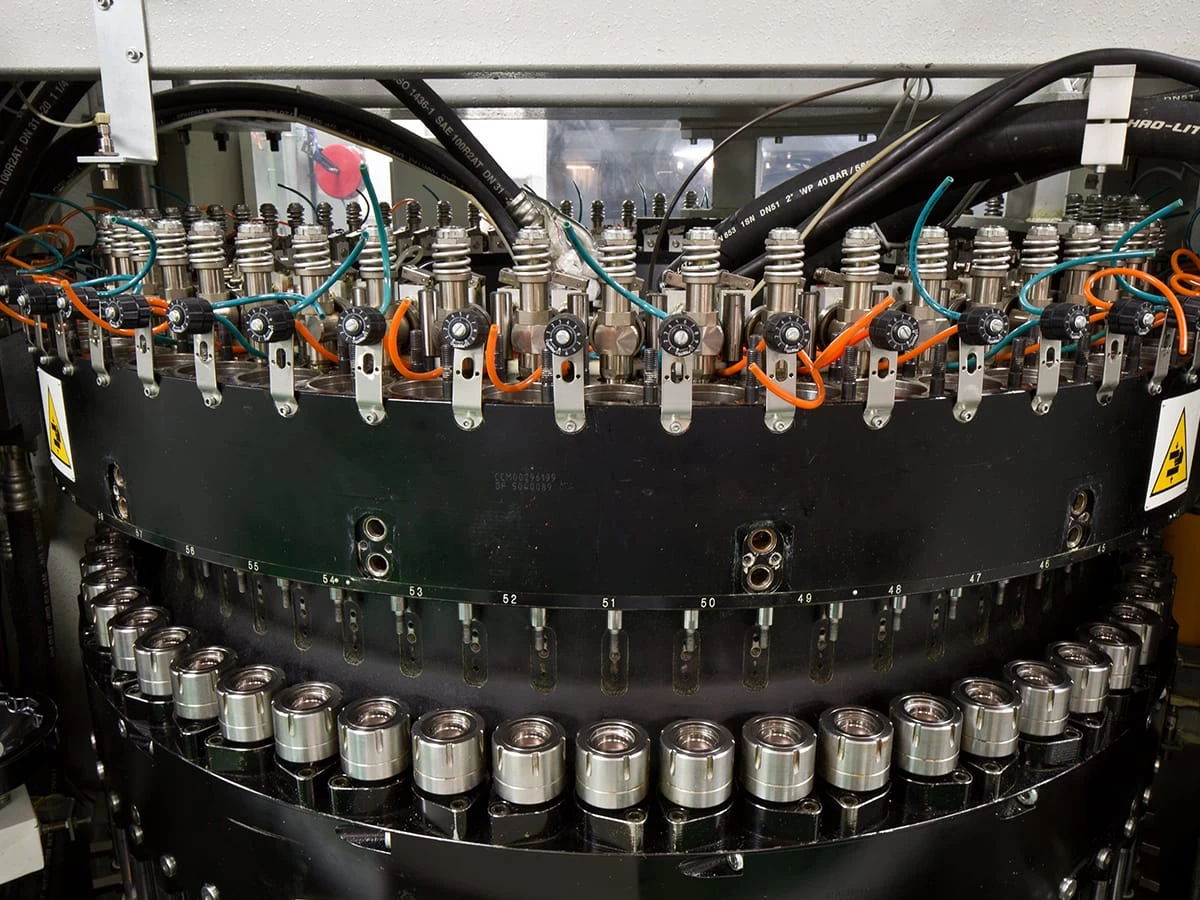

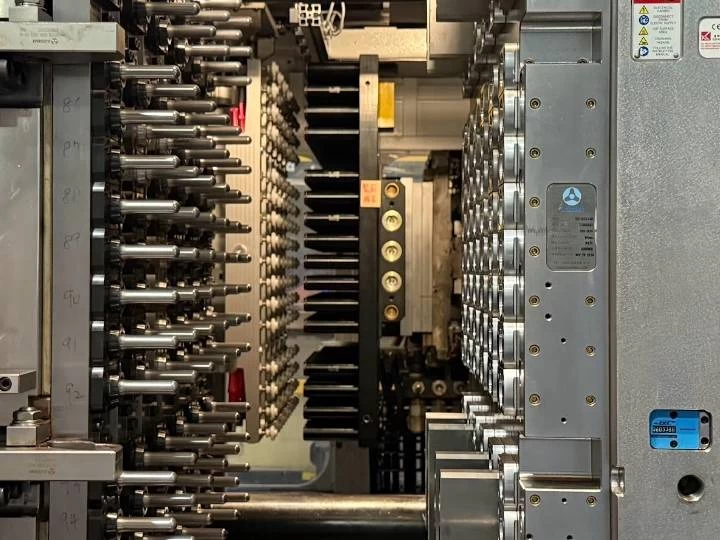

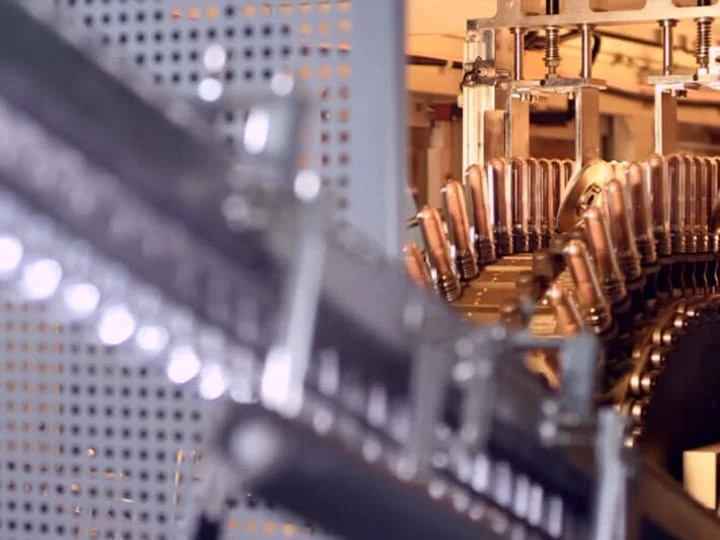

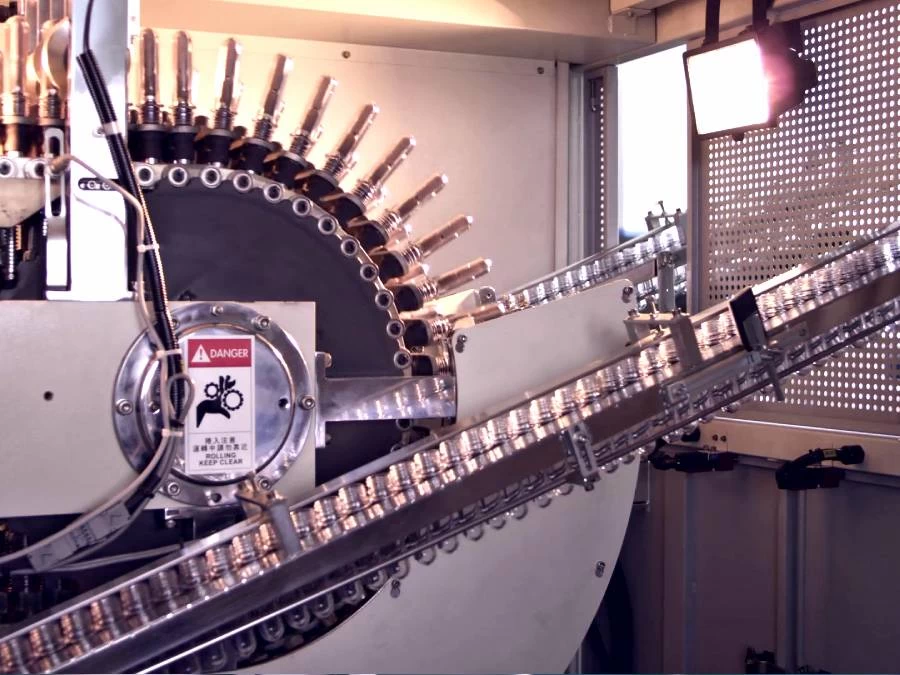

Production equipment for plastic closures

Production equipment for plastic closures

Production equipment for plastic closures

Production equipment for plastic closures

Production equipment for plastic closures

Closure Production System

Core Equipment

- High-speed closure compression molding machines

- Injection molding machines

Process Description

- Plastic resin is heated and melted, then formed by compression molding.

- In-line vision inspection system for real-time monitoring of cap appearance and quality.

Equipment & Process Advantages

- High efficiency, low energy consumption

- High consistency: Low mold wear ensures stable dimensions and sealing performance.

- High flexibility: Supports various application requirements.

Preform crystallization machine

Preform crystallization machine

Preform crystallization machine

PET bottle blowing machines Sidel | Krones | Corpoplast

PET Preform & Bottle System

Core Equipment

- PET preform injection molding machines

- Preform neck crystallization systems

- High-speed blow molding machines

Process Description (2-step ISBM)

- Preform stage: Injection molding with optional neck crystallization for heat resistance.

- Blow molding stage: Preforms are reheated and stretch blow molded into bottles (in-line or off-line).

Equipment & Process Advantages

- Heat resistance: Crystallization enables hot filling without deformation.

- Lightweight design: Supports thinner and lighter bottle structures.

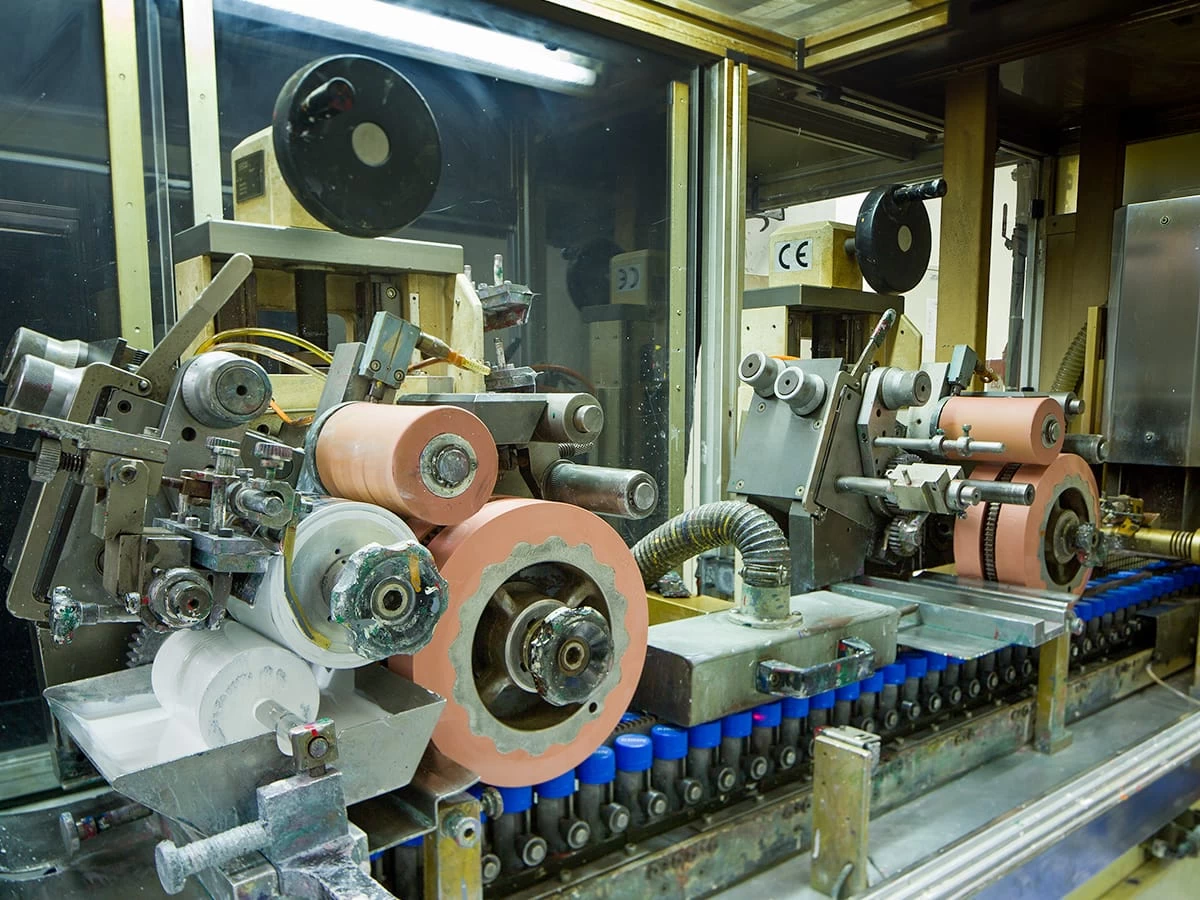

Slitting machine

Sleeve seaming machine

LDPE shrinkable film

Label Printing & Converting System

Core Equipment

- High-speed flexographic printing machines

- Slitting machines

- Rewinding and laminating machines

Process Description

- Covers printing, slitting, cutting, and rewinding processes.

- Uses eco-friendly UV inks.

- Supports PET, PVC, and OPS shrink films.

Equipment & Process Advantages

- Environmentally friendly: Reduced VOC emissions.

- High color registration: Wide color gamut printing with reduced ink waste.

HPP systems

HPP systems

HPP systems

HPP systems

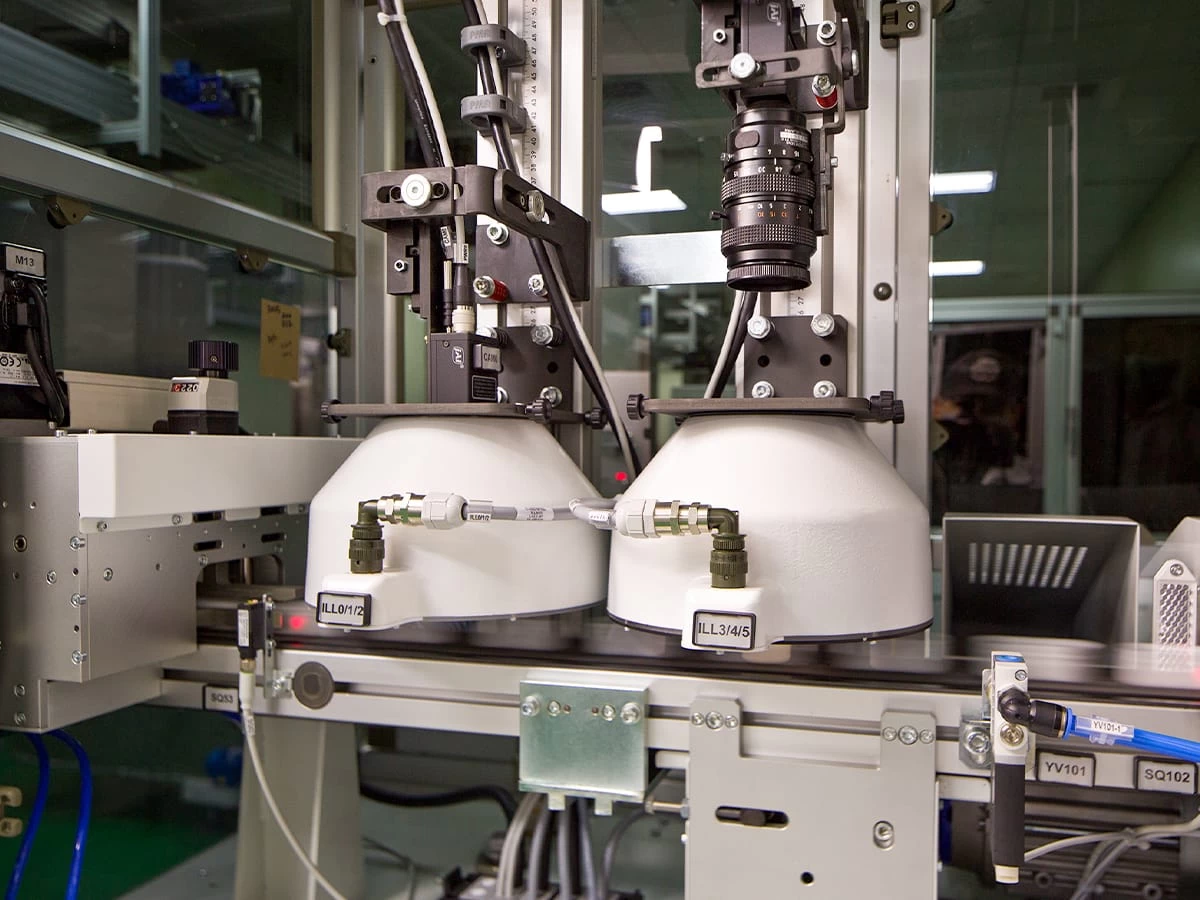

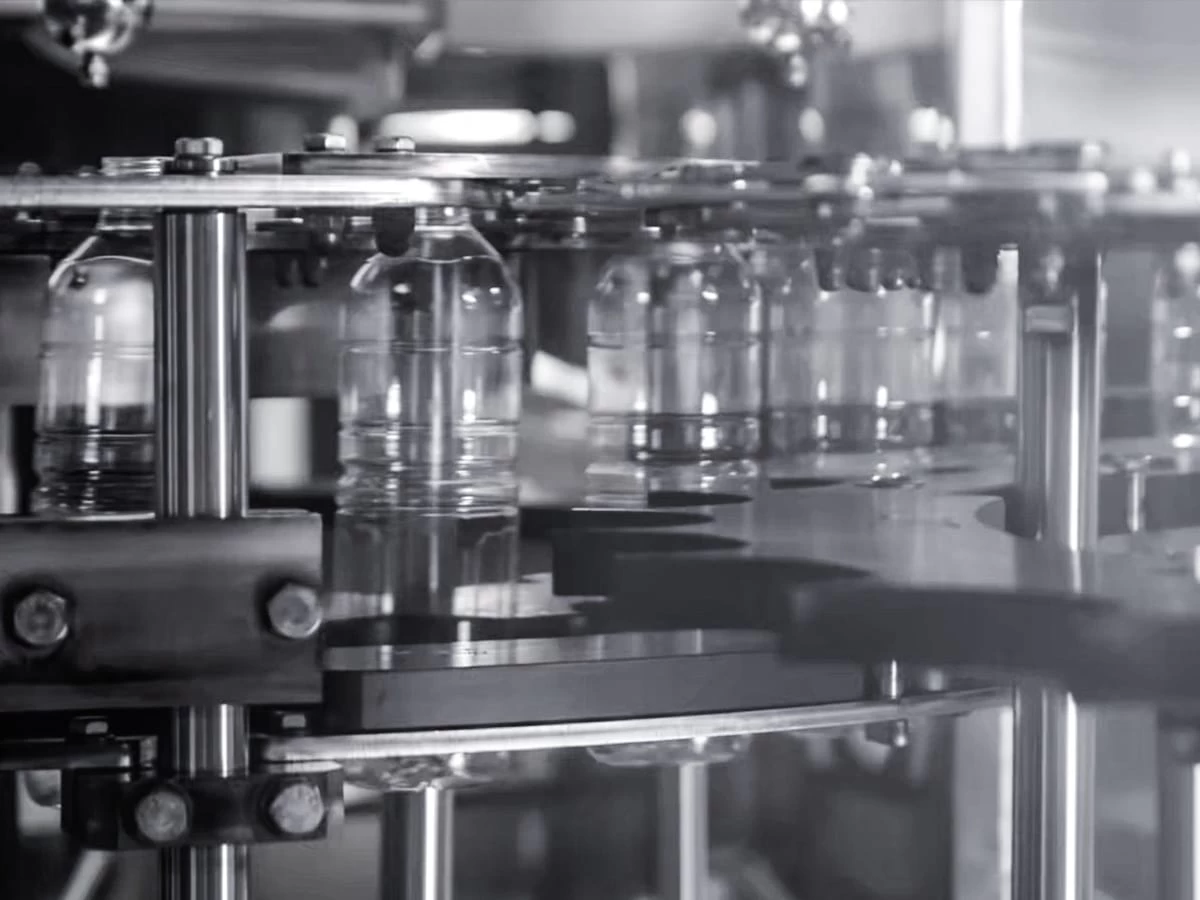

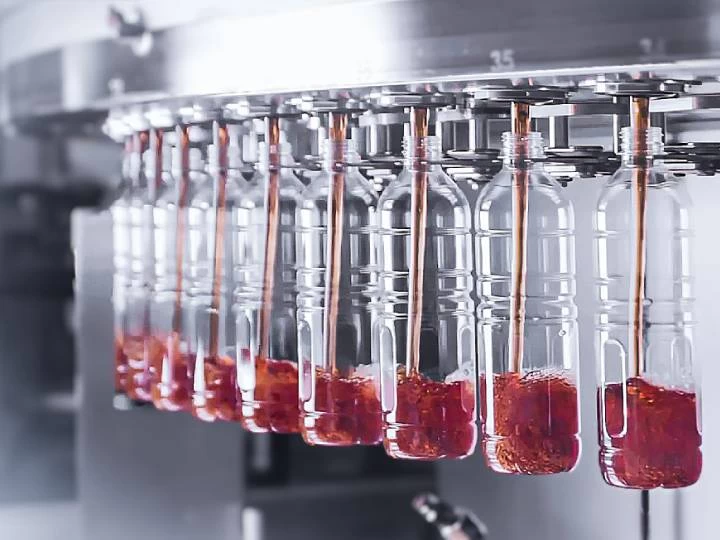

Filling equipment

Filling equipment

Filling & Packaging Lines

Core Equipment

- Aseptic filling lines

- Hot filling lines

- HPP systems

Process Description

- Includes container washing, filling, capping, and downstream packaging.

- Aseptic process: Cold filling in Class 10,000 cleanroom environment.

Equipment & Process Advantages

- Food safety: ISO 22000 and HACCP certified, with automated monitoring.

- Flavor retention: Aseptic cold filling or HPP reduces thermal impact.