Your Trusted Partner in Global Beverage Manufacturing

For decades, HON CHUAN has been dedicated to beverage manufacturing and the production of beverage packaging materials—including PET bottles, caps,preform and labels—earning long-term recognition and trust from customers worldwide.

As a professional drink manufacturer, we offer a 4-in-1 complete beverage solution that integrates caps, PET bottles, labels, and filling. This vertically coordinated system enables efficient production and professional alignment between manufacturing and marketing.

With extensive OEM experience, HON CHUAN also provides private label beverage manufacturing services, supporting brands in developing customized products that meet international standards and adapt to evolving global market trends.

Filling type

Bottled Water Filling OEM

Hotfill Beverage

Aseptic Beverage

Packaging type

PET

TR

TBA

1 Water Treatment

Our water sources is used the most advanced automated systems for water treatment including multilayer purification, activated carbon deodorization, ionic-exchange resin to soften water and RO reverse osmosis. Our water complies with the government’s safety standards for drinking water and gives products the finest taste.

2 Raw material inspection

3 Mixing

The dissolution of sugar and powder, formulation is monitored and controlled by automatic computer system.

4 Sterilization

UHT(Ultra-High-Temperature) Sterilization

5 Filling

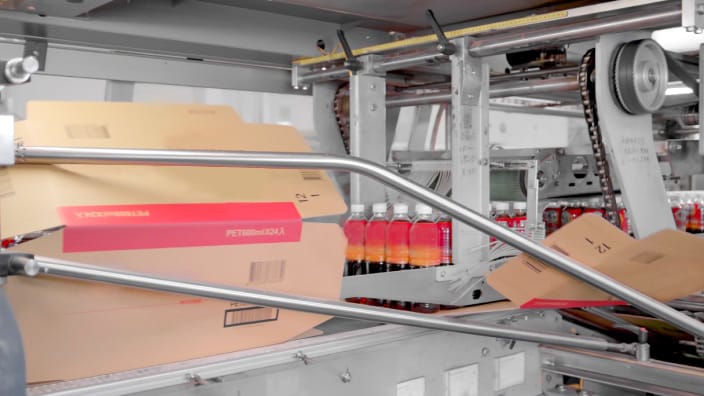

We use an integrated 3 in 1 machine(bottle blowing+filing+capping), this system can save space and reduce the energy consumption

6 Labeling

High-speed labeling machines

7 Quality Control

THC have inspection machine and QC to check every finish product, we can ensure our quality control that can fulfill customer standard.

8 Packing

Our system can offer variety of packing methods such as carton box, tray pack and shrink pack.

9 Storage

THC has engaged the ASRS (automated storage and retrieval system) for high efficiency storage.

10 Microbiological Examination

After production, the microbiological examination is conducted for every product to pass the commercial release and shipment.